The Buzz on Sheroz Earthworks

The Buzz on Sheroz Earthworks

Blog Article

All about Sheroz Earthworks

Table of ContentsSheroz Earthworks Can Be Fun For EveryoneNot known Details About Sheroz Earthworks Fascination About Sheroz EarthworksIndicators on Sheroz Earthworks You Should KnowNot known Incorrect Statements About Sheroz Earthworks

For any type of earthwork service provider, it is vital to do deal with top quality, precision, and on time. Making use of machine control in work equipments enables maximizing the various stages in the earthwork procedure, from intending to the maintenance stage - topcon laser level. The device control system helps the machine driver in obtaining the target plane rapidly and quickly

The machine control system overviews the operator with centimeter accuracy. With Xsite PRO 3D, you'll constantly recognize specifically just how much to cut or fill. Your neighborhood Xsite technological support can assist you and aid with any issues without checking out the site. Remote assistance conserves time and cash, as it lessens downtime in jobsites.

What Does Sheroz Earthworks Do?

Added training and directions are always readily available over remote assistance when required. The earthmoving industry has used our field-proven options considering that the early 1990s. Our system's parts are meticulously created to endure the rough problems of building and construction websites. Comparison of the same task executed utilizing machine control versus the conventional technique reveals that, usually, the standard strategy calls for 50% more time to achieve the very same job as the technology-assisted method. https://myspace.com/sherozau.

Seems great? Get in the Xsite machine control system; it's below to provide you with a significant benefit when working with earthmoving machinery. Discover exactly how Xsite Equipment Control can enhance your efficiency and guarantee job safety and security! We understand that finding out a new technology could seem like a drag, yet do not stress! Our pleasant and professional local assistance services have actually obtained you covered, guaranteeing that you can keep working smarter without disruptions while on duty! With remote assistance, your neighborhood Xsite dealership can offer guidance or troubleshooting without needing to check out the website! What type of excavators does maker control fit? Xsite Machine Control systems can be set up to any kind of excavator from mini excavators to huge mining excavators.

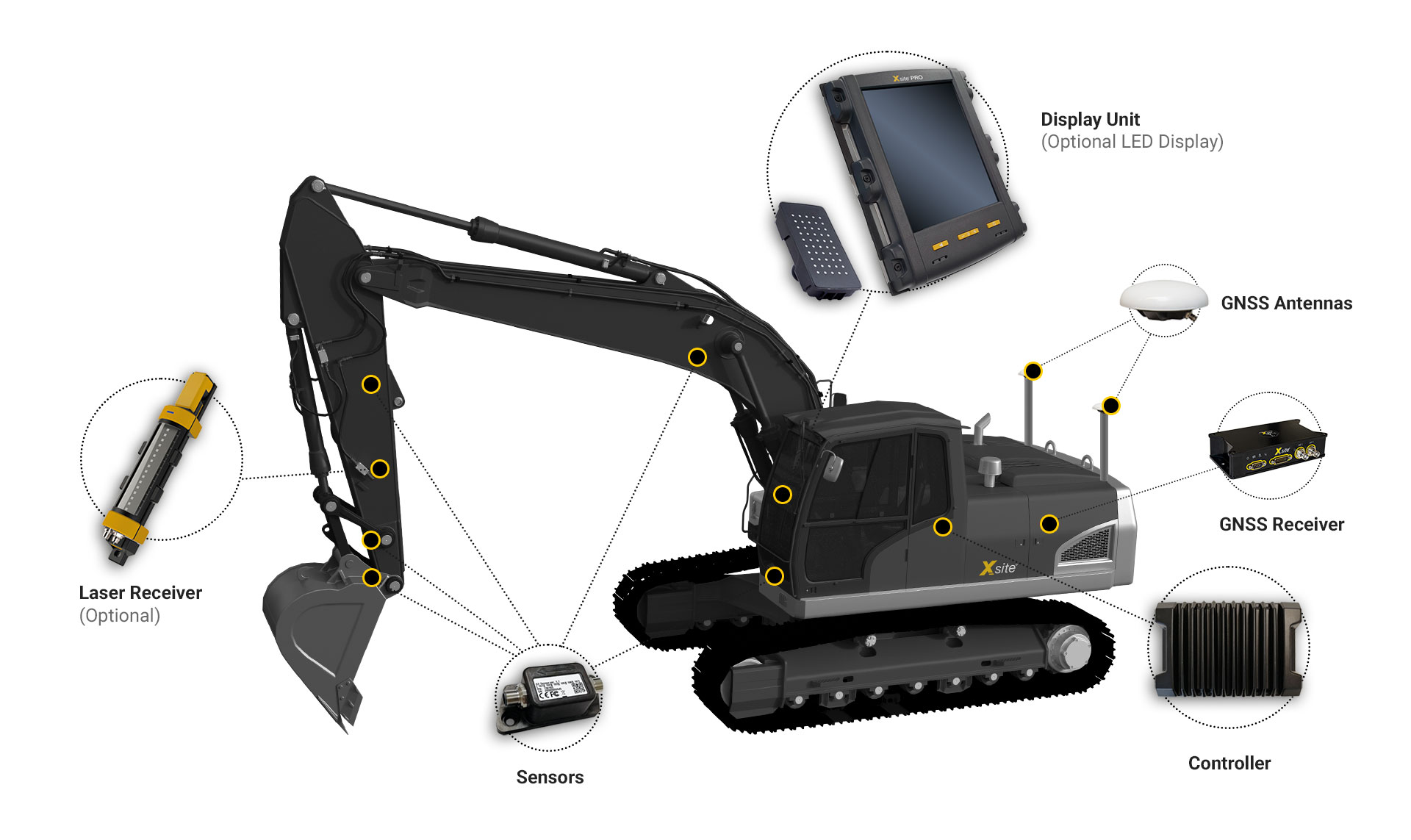

Exactly how does machine control work? In 2D systems, the machine is geared up with calibrated inclination sensors. These sensing units are mounted on the pre-determined parts of the device in excavators the sensing unit are generally mounted to the structure, boom (or booms), miner arm and to the fast coupler - topcon laser levels. By utilizing the data advice obtained from these sensors the system can determine the precise placement of the excavators bucket pointer in significance to a referral factor.

The system is extremely simple to find out the essentials can be educated in under one hour of training. Exactly how does the remote support work? A wireless net connection makes it feasible to establish a remote connection between the machine control system and the solution.

9 Easy Facts About Sheroz Earthworks Described

Xsite Equipment Control systems sustain open typical data formats, enabling seamless info flow from one system to another. Depending on your selection of system (with or without positioning, i.e., 2D or 3D), your maker is furnished with inclination sensors, a controller unit, and a display/operating panel.

Lots of software and hardware options exist to help establish a maker's current placement on the planet and contrast it with a desired design surfaceand building and construction drivers can do more to leverage the advantages. Maker control is the use of different placing sensors and a screen to give the driver with a referral between the placement of the bucket or blade and the target quality.

Depending upon the setup, machine control systems can offer the driver with a simple aesthetic guide to bucket or blade position, or can automatically relocate the blade to quality by speaking to the maker's hydraulics - https://sitereport.netcraft.com/?url=https://sheroz.com.au. There are maker control systems available for almost any equipment: graders, dozers, excavators, soil and asphalt compactors, scrapes, trimmers, crushing makers, and pavers

The Sheroz Earthworks Ideas

Device control can additionally help boost efficiency and minimize total expenses. Building and construction devices without maker control will end up being a point of the past and the advantages got from it will certainly be countless.

Trimble equipment control systems offer a myriad of advantages to anybody who uses earthwork machinery and, at EarthCalc, we can give you with 3D files for your equipment control-enable tools. Uncertain if maker control is worth the cost? Think about the adhering to reasons you need to consider this alternative.

Making use of GPS lined up with your 3D design documents, these systems practically ensure that you will get rid of or place the correct amount of material at the building site. On most building and construction websites, revamp is a common and frustrating fact, but with Trimble device control, you can get rid of the need for rework.

The Facts About Sheroz Earthworks Revealed

Often, with Trimble machine control, you can eliminate excess tools at a specific work site. For circumstances, a task that may have called for the use of three or four items of excavating tools now may require just 2 tools to achieve the very same task in less time. This enables you to move your equipment to one more job site and handle multiple tasks at one time.

Report this page